Introduction

If you decide to make a drone from scratch

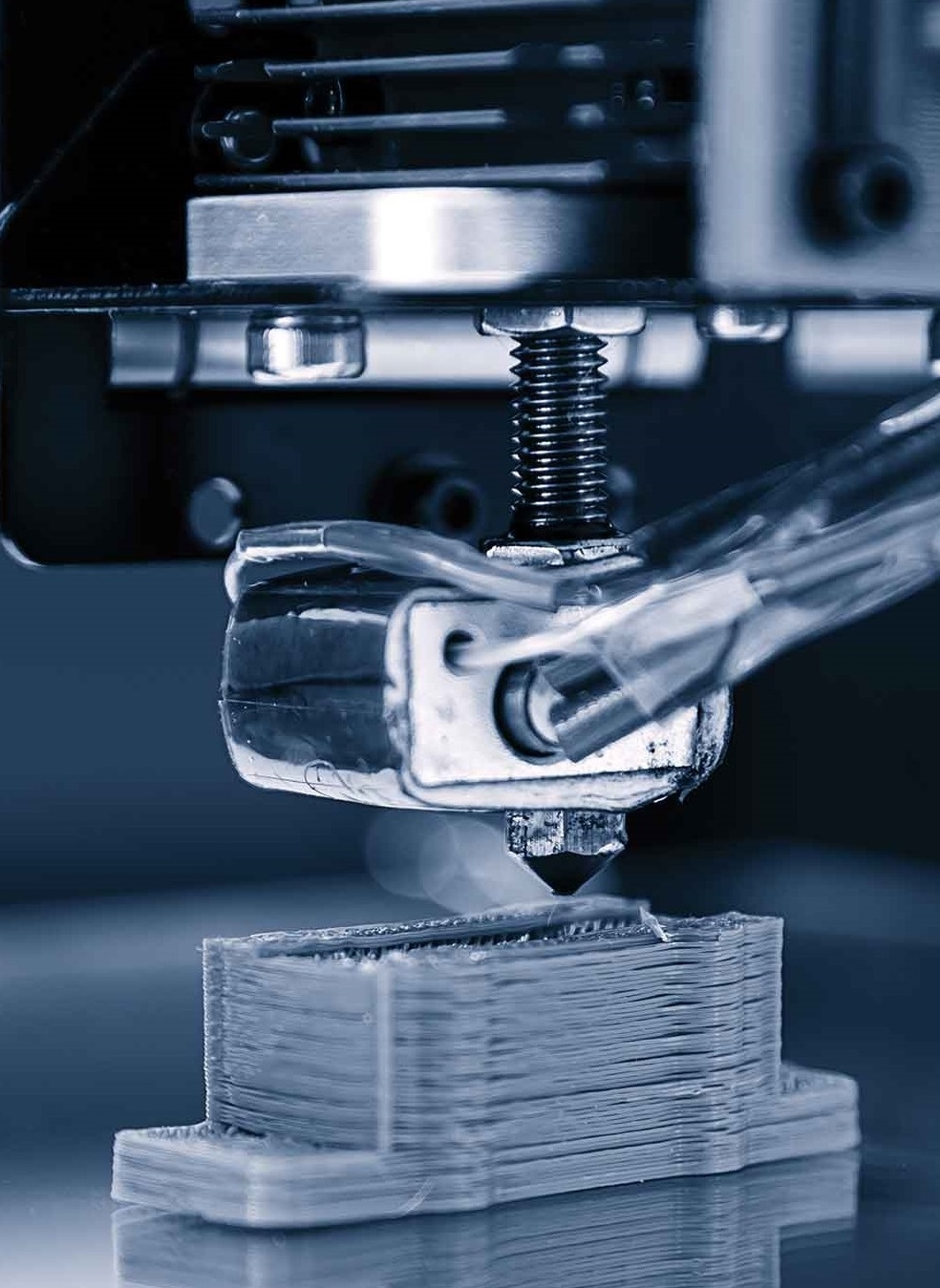

Basics of 3D Printing Drone Parts

5 '' Mini Quad with Printed Mount for Hero 8 (Source: Rob Davie via All3DP)

Unmanned aerial vehicles (UAVs / UAVs / UAVs), also known as drones, are vehicles that can operate autonomously. In other words, a drone is not necessarily an aircraft; they can also include cars, boats and even hovercraft. However, the term is used to describe an aircraft that has three or more rotors to provide lift and thrust. They are also commonly referred to as multicopters, tricopters, quadcopters, and so on.

In general, UAVs are mechanically very simple and consist of a frame, flight controller, el. motors, propellers, speed controllers, and possibly FPV equipment.

3D printing has long proven itself in the drone hobby. This technology allows the user to easily manufacture many different parts on their own. This can be anything from protective bumpers and action camera mounts, to accessories that add functionality to the quad.

In this article, we'll talk about what to consider when 3D printing drone parts, analyze the most relevant parts for printing, and also tell you where to find models and resources. We will then wrap up the material with a few projects to help you get started. But first, let's figure out why you need to 3D print parts at all. Read on to find out more!

Benefits

Smartphone Holder (Source: Digit Design and Prints via Facebook )

- The main advantage of 3D printing parts is that they can be completely customized. In addition, they tend to be inexpensive (assuming you already have a printerfilament (3D printing filament)

- Printed parts can be made from different materials in different colors. This approach allows the use of a material with the best mechanical properties for specific elements. For example, your GoPro mount can be blue TPU and your propeller guards nylon. Camera holders are best printed with TPU (Thermoplastic Polyurethane; TPU), as this material absorbs vibration from the frame and holds the GoPro tightly in place, while the durable nylon can absorb shock and protect both the propellers and the object / obstacle itself. Other durable materials such as reinforced nylon can even be used to create gliders, awnings and camera gimbals.

- Another plus when using printed parts is their relatively low density. With the help of 3D printing, parameters such as the number of perimeters and percentage of infill can be adjusted in order to significantly reduce weight, and the former largely determines the final result.

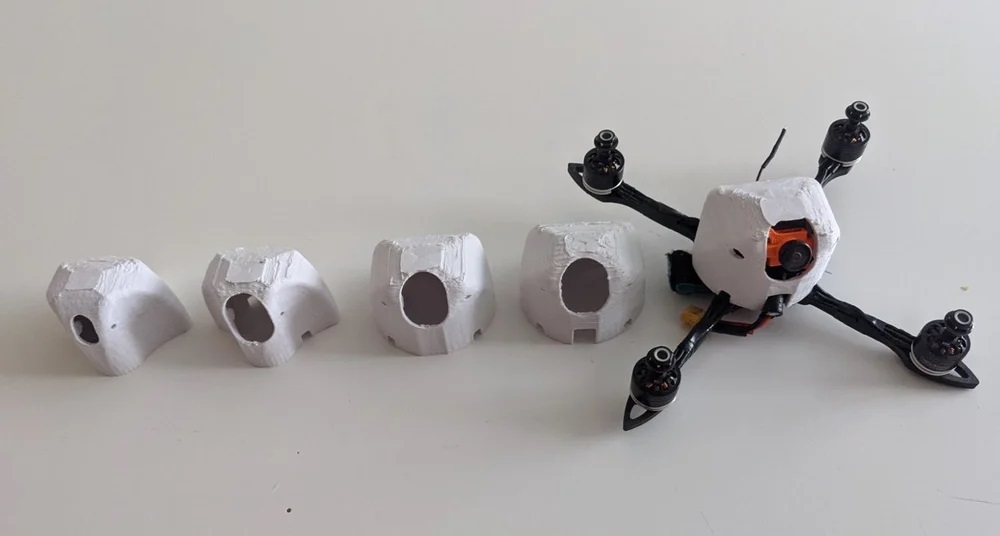

This photo shows the sequence of making a canopy for an FPV drone (Source: Rob Davie via All3DP)

- While the parts to be manufactured are fully customizable and lightweight, they can be quickly iterated over. For example, when designing a canopy, the first version of the blank can be printed from an inexpensive material such as PLA, and after the fitting process, any required changes can be easily made in the next iteration. Once the model is finished, it can be printed with more expensive material such as carbon fiber, nylon, or even, if budget allows, PEEK carbon fiber.

- In addition, if you have a printer and filament, the problem of a broken part becomes irrelevant, since you can start creating a new one right away. Even though many retailers offer fast shipping, it will always be best to print the part yourself.

Considerations

Do you need all of these components? (Source: Rob Davie via All3DP)

While 3D printing opens up a whole new world of possibilities in terms of additional features, the most important thing to remember is the weight of your aircraft. Not everything that can be printed and installed is advisable! It should be understood that each gram of a drone affects the flight time and flight characteristics, especially for rotary-wing aircraft. In other words, on a UAV, the primary purpose of which is long-term flight, the presence of such components as a mount for GoPro, a head tracking device and a reset mechanism is not necessary.

You may also notice that large companies such as DJIsimilar aircraft

In addition, in many countries, including the Russian Federation, the rules require to register models weighing more than 250 grams. Accordingly, the demand for quadrocopters weighing below this limit is much higher.

The best materials

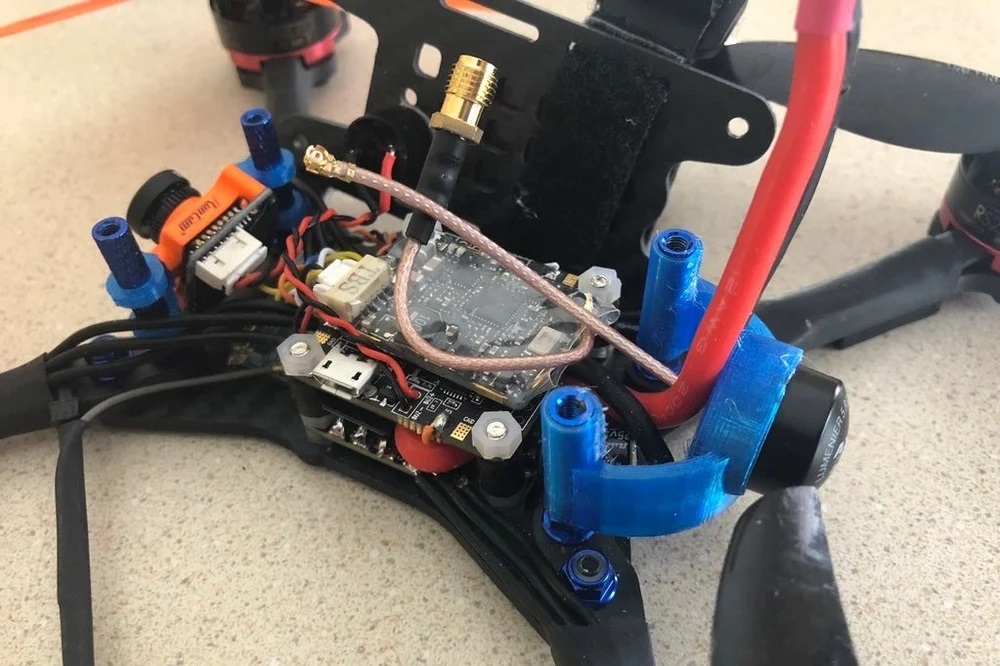

Beam guards, GoPro mount and antenna mount are all printed from TPU (Source: Digit Design and Facebook Prints )

The most commonly used material for the construction of copters (especially relevant for the mini niche) is TPU. This is because it is very flexible and can deform on impact, absorbing energy and protecting important components of the UAV. Due to its flexibility, it can also absorb vibration, reducing the amount of visible artifacts in the recorded video. Fortunately, this has become less of an issue with the introduction of in-camera stabilization. Another suitable material is nylon. It is stiffer than TPU, but still has some flexibility.

Material suitability

The main parts printed on the TPU are bumpers, camera mounts, antenna mounts and propeller guards. Nylon can also be used to protect props, but is less common because it is more difficult to print.

While TPU and nylon are versatile in use, they are not suitable for all parts. In applications where more rigidity and strength is required, for example in the manufacture of airframes, a material such as carbon-fiber-reinforced nylon ( carbon-fiber-reinforced nylon; abbreviated CFRPA6

One way to protect the undersides of the boat frame, as well as the mounting bolts of the motors, is to add 3D printed “ stands or landing pads

Variety of parts

5-inch tandem racing quadcopter with turtle or turtle mode (Source: Rob Davie via All3DP)

Fins

If your hobby is racing drones, then you should try using a fin. This component is especially useful in tandem with a regime known as "turtle or turtle". When the drone is tilted upside down, thanks to the fin, two motors free from contact with the surface will be able to rotate unhindered, which will subsequently allow you to quickly flip the quad and continue the race. Most often they are printed from TPU and sometimes from nylon.

Antenna mount

FPV transmitter antenna holder printed in TPU ( Source: rapnit via Thingiverse )

When flying in FPV mode, VTX antennas are vital. Thus, there are many options for mounting such components. If the device is intended for long-distance flights, then enclosing the active part of the antenna in the TPU is not a good idea, since this will negatively affect the video signal. For them, TPU is the preferred choice because it is very elastic and can deform without breaking for a long time.

You can also enable FPV head tracking when an FPV cameraFPV goggles.... In this way, the camera follows the movements of your head, contributing to greater immersion. For this, inflexible materials such as PETG, ABS, ASA or even PC should be used. Rigidity is necessary to eliminate backlash in the components.

Functional components

A 2-axis gimbal (to stabilize the camera) was printed in PLA (Source: turbi via Thingiverse ).

If FPV flying or racing is not for you, you can always print the details to expand the functionality. Is it a camera stabilizer for aerial photography or video filming, or a mechanism for capturing and dropping objects? For gimbal gimbals, moving parts must be printed on a non-flexible material to ensure there is no backlash. When installing the gimbal on a drone, there must be a flexible piece between the gimbal and the gimbal to isolate it from vibration

Guard

This stick guard was developed in Fusion 360 (Source: Motorpixiegimbals via Thingiverse )

Finally, another good option for printing is protection parts such as control sticks. They can be flexible or inflexible, depending on your preference.

Model Sources

Search results for "Drones" on GrabCAD ( Source: GrabCAD )

- Thingiverse is a great free resource for finding mounts for public cameras (GoPro, Insta 360, etc.) and frames (TBS Source One, ImpulseRC, Iflight, etc.).

- GrabCAD is another popular free resource that tends to offer more engineering models, however there are still quadcopter related models on the list. Please note that you will need an account to download the models (which is remarkable for Thingiverse this is not necessary). If you download models from any repositories (including the websites listed above), be sure to check the license under which they are located to ensure that no copyright infringement occurs when sold.

- If you happen to have a specific frame or camera, remember that the manufacturer of those components often has design data available for download and printing. In this case, this approach will be most useful, because the likelihood that the part will match yours may be higher than if you use data from a third-party website.

- If you can't find what you need anywhere, you can design your own parts in CAD software or have someone else design it them for you.

Resources

This site has an active user base and many helpful discussions. ( Source: DIYDrones )

While many individual components can be downloaded from the sites listed above, there are additional resources such as forums. The main drone maker forums are DIYDrones and RCGroups. A complete list of printable gliders on RCgroups can be found in one helpful thread, or similar lists can be found at DIYDrones. In addition, there is a drone subreddit that discusses 3D printing topics, and a DIY drone subreddit.

Projects to Get You Started

Kanupi model with custom molded GoPro holder ( Source: basdelfos via Thingiverse ).

The only real limit to what you can print is your imagination! Before proceeding, you will need to consider the intended use of both the drone and the parts, as well as the effect of any additional weight.

We bring to your attention the following ideas from Thingiverse affecting printing, whether it is an entire copter or just its individual parts:

- Quadrocopter: family frames that can be fully 3D printed (dozens of versions and variations)

- Stick protection: protects control equipment sticks during transport

- Canopy for FPV drone: example of canopy, with molded GoPro mount (pictured above)

That's it. Thank you for the attention. We hope the presented material was useful for you. Stay with us!

Videos

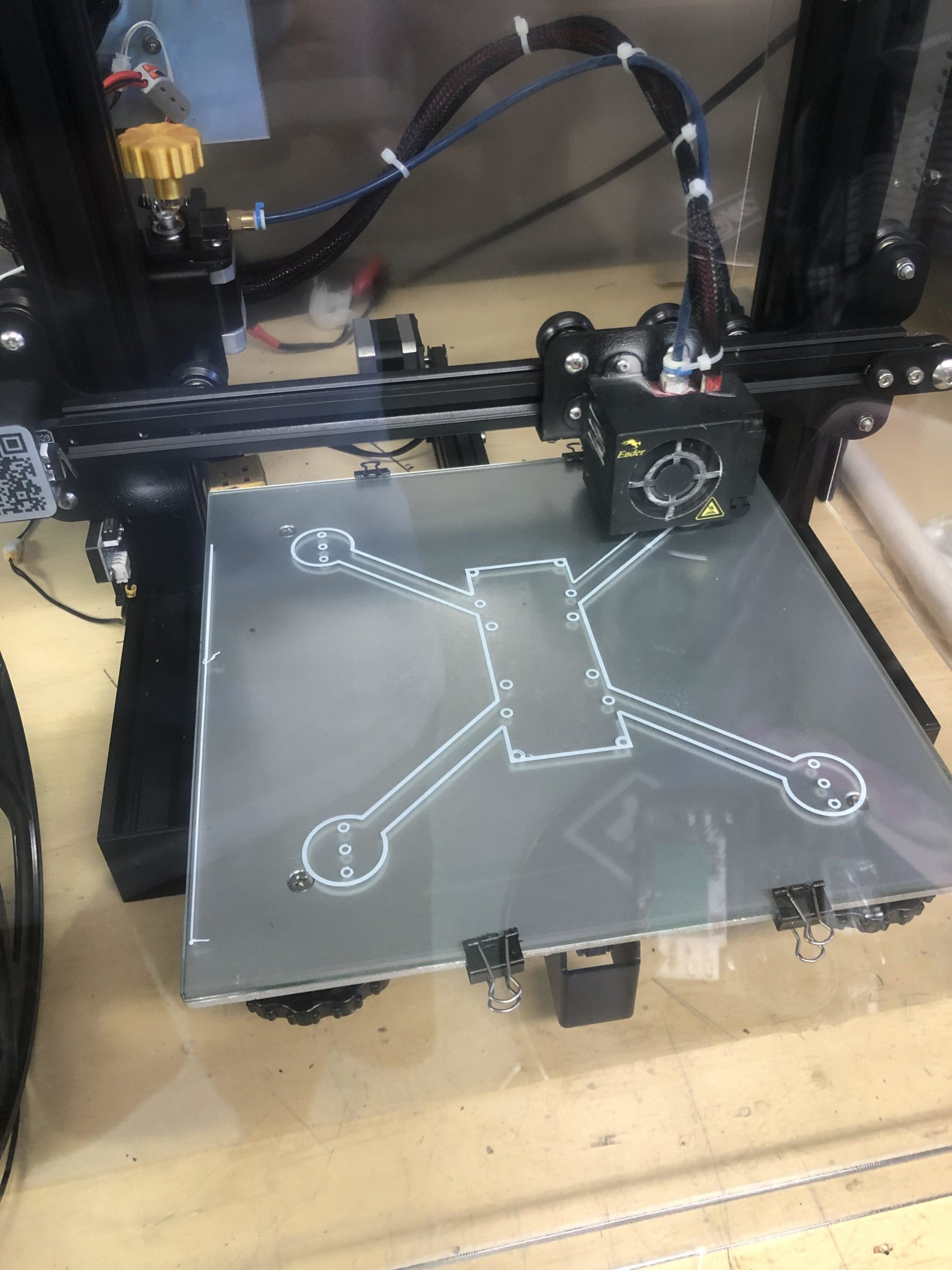

An illustrative process of printing beams for an FPV drone made of carbon fiber reinforced nylon (CFRPA6).

.