Introduction

Surely every newcomer who first connected his life with electric models on radio control, after a thorough study of the filling, has a question. What is a Brushed and Brushless Motor? Which one is better to put on your radio-controlled electric model?

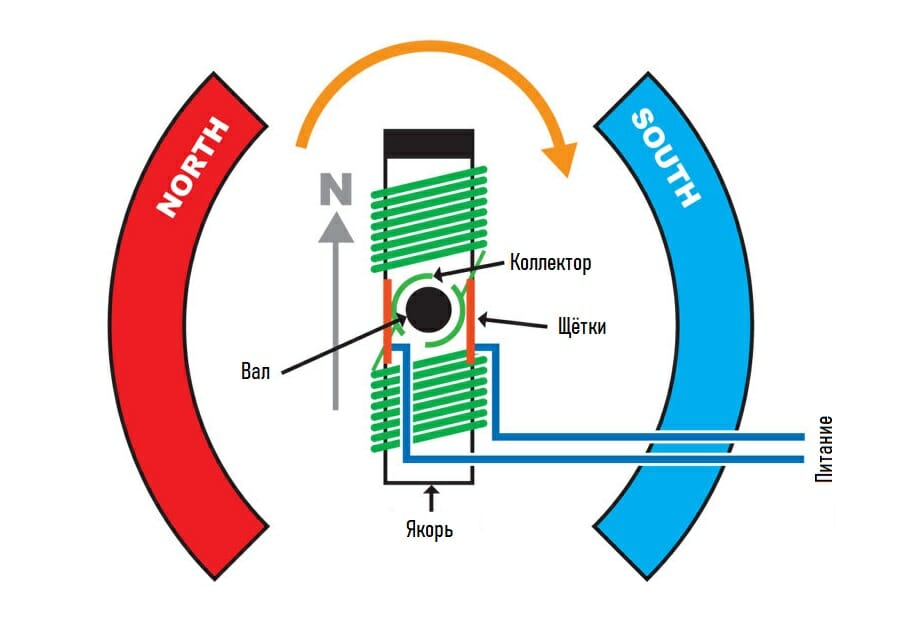

The commutator motors that are so often used to propel radio-controlled electric models have only two outgoing supply wires. One of them is "" the other is "-". In turn, they are connected to the speed controller. Having disassembled the collector motor, you will always find there 2 curved magnets, a shaft together with an anchor, on which a copper thread (wire) is wound, where there is a gear on one side of the shaft, and on the other side there is a collector assembled from plates, which include a clean copper.

The principle of operation of the collector motor

Electric current (DC or direct current), entering the armature windings (depending on their number for each in turn) creates an electromagnetic a field that has a south pole on one side and a north pole on the other.

Many people know that if you take any two magnets and attach themwith the poles of the same nameto each other, then they will not converge for anything, and if you put opposite ones, they will stick so that they do not it is always possible to separate them.

So, this electromagnetic field, which occurs in any of the armature windings, interacting with each of the poles of the stator magnets, drives (rotation) the armature itself. Further, the current, through the collector and brushes, goes to the next winding and so sequentially, passing from one armature winding to another, the motor shaft rotates together with the armature, but only as long as voltage is applied to it.

In a standard collector motor, the armature has three poles (three windings) - this is done so that the motor does not "stick" in one position.

Disadvantages of collector motors

By themselves, collector motors do a good job with their work, but this is only until the moment there is a need to get from them at the output of the highest possible speed. It's all about the very brushes mentioned above. Since they are always in close contact with the collector, as a result of high revolutions at the point of contact, friction arises, which will subsequently cause rapid wear of both and subsequently lead to a loss of effective power of the el. engine. This is the most significant disadvantage of such motors, which negates all its positive qualities.

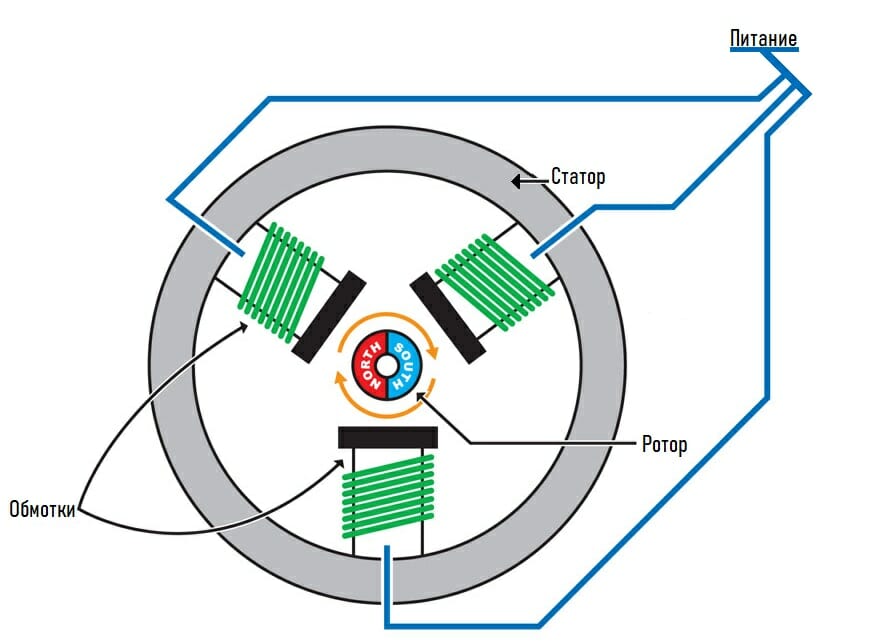

The principle of operation of a brushless motor

Here the opposite is true, the motors of the brushless

Brushless motors can be with or without a sensor. The absence of a sensor slightly reduces the efficiency of the motor, so their absence is unlikely to upset a beginner, but on the other hand, the price tag will pleasantly surprise. It is easy to distinguish them from each other. For motors with a sensor, in addition to 3 thick power wires, there is also an additional loop of thin ones that go to the speed regulator. You should not chase motors with a sensor for both a beginner and an amateur, because their potential will be appreciated only by the pros, and the rest will simply overpay, and significantly.

Advantages of brushless motors

Almost no wearing parts. Why "almost", because the rotor shaft is installed on bearings, which in turn tend to wear out, but their resource is extremely long, and their interchangeability is very simple. These motors are very reliable and efficient. A rotor position control sensor is installed. On collector motors, the operation of the brushes is always accompanied by arcing, which subsequently causes interference in the operation of radio equipment. So with the bezkollektonyh, as you already understood, these problems are excluded. No friction, no overheating, which is also a significant advantage. Compared to collector motors, they do not require additional maintenance during operation.

Cons of brushless motors

These motors have only one minus, this is the price. But if you look at it from the other side, and take into account the fact that the operation of brushless motors frees the owner immediately from such troubles as replacing springs, anchors, brushes, collectors, then you will easily give preference in favor of the latter.

.